Woven Wire Mesh for Paper Making

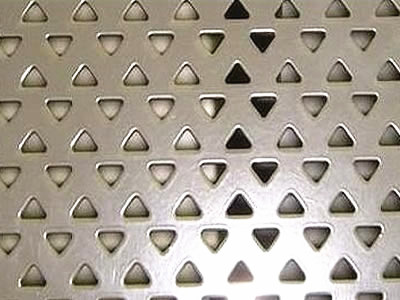

Woven wire mesh is the ideal material for pulp and paper industry. It use the wire mesh for water clarification,dewatering, pulp screening and fractionation, drying and other liquid/solid separation processes. Create without boundaries with wire mesh available in different types of metals, finishes, and opening sizes.

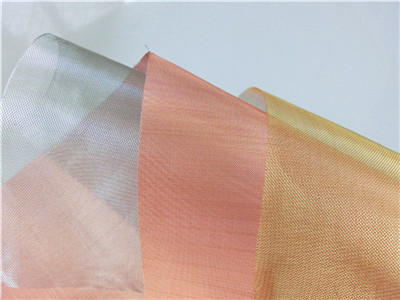

Woven wire mesh metals

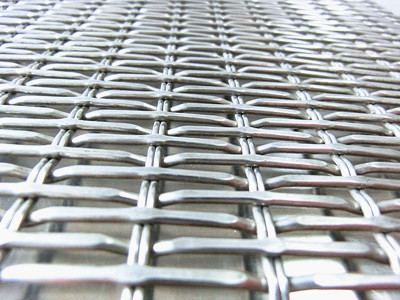

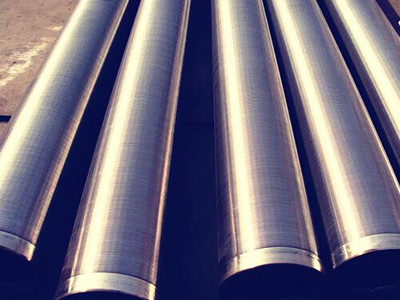

Stainless steel mesh

The stainless steel woven mesh offers many benefits for paper making. The stainless steel materials bring added toughness to the table. It is available in fine opening sizes to properly filter and separate plant material from the water.

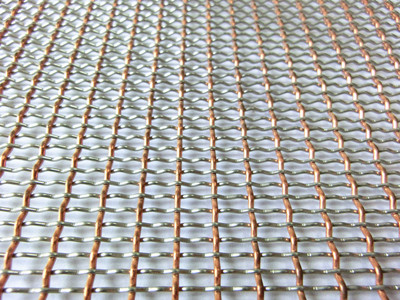

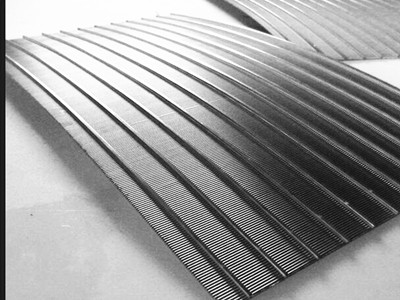

Brass wire mesh

For its standout flexibility, the brass wire mesh is used for papermakers. The brass combines copper and zinc to create a relatively soft and bendable product. It is also available in fine opening sizes.

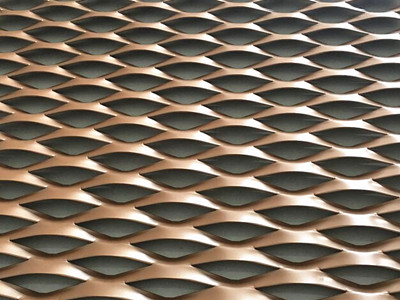

Bronze wire mesh

The bronze wire mesh is widely used in the papermaking industry. The bronze brings a special combination of copper and zinc to fit a range of technical and decorative projects. The bronze mesh is also available in fine opening sizes.

Mesh sizes

The commonly mesh sizes for papermaking is 20mesh to 100mesh. The selection of wire mesh size depends on the amount of short fiber it is desirable to include in the pulp. The smaller the mesh openings, the more short fiber and clay will be retained and the less the hydraulic loading can be exerted per square meter of mesh surface area.