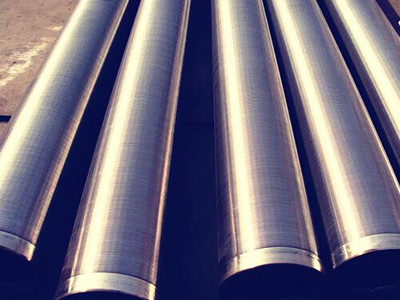

Wedge Wire Screen Tube for Oil & Gas Well

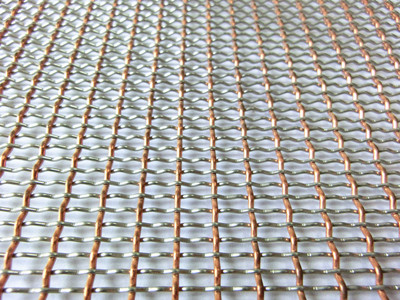

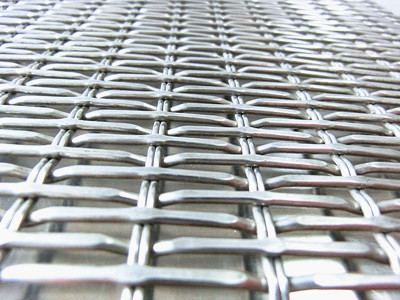

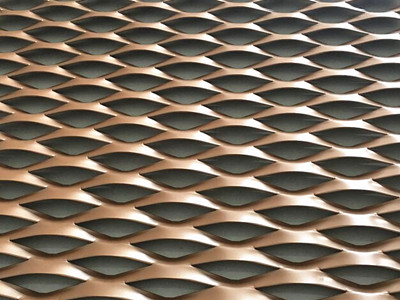

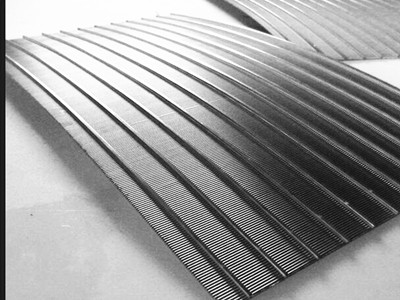

The wedge/Vee wire screen technology combines excellent weld strengths and accurate slots tolerances. A great quantity of rods increases the tensile strength and achieves rounder and stronger screens. The wedge wire screen tube is widely used in the oil & gas well industry. Wedge wire well screens are usually attached to the bottom of the casing, if pumps water from a sand-gravel aquifer. The wedge wire well screens are extend into the aquifer and allow water to move through the gap, while preventing sand and gravel from entering the water well.

The water wells completed with gravel pack is the best way for sand control. In the processing, sand or gravel is placed outside the wedge wire screen, between the screen and the bore hole wall, that better to prevents fine sediment from entering the screen and also promotes water move into the well.

Benefits

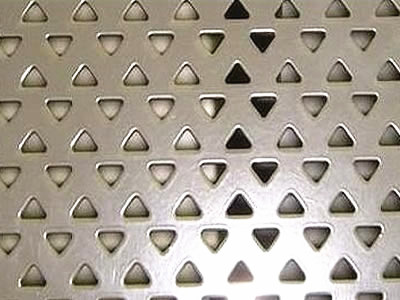

Non-clogging (blinding/pegging) - the continuous slot formed by the V-shaped surface wires ensures a two- point contact between the particles and the slot,which minimizes clogging of near size product.

High-precision slot sizes - precise/exact aperture can be achieved.

Surface Filtration - the V shaped surface wires allow easy cleaning by mechanical scraping,back flushing or high pressure hose.

Strong construction - for most applications the wedge wire is self-supporting because of the welding at each intersection and can therefore withstand high pressure(Psi) and heavy loads.

Applications

Openhole and cased-hole completions

Vertical, deviated and horizontal completions for oil and gas wells

Inflow and injection control wells

Thermal applications

Standalone and gravel pack completions