The difference between hot dipped galvanized expanded metal and electric galvanized expanded metal

The difference between hot dipped galvanized expanded metal and electric galvanized expanded metal

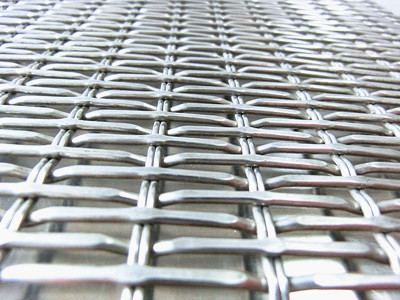

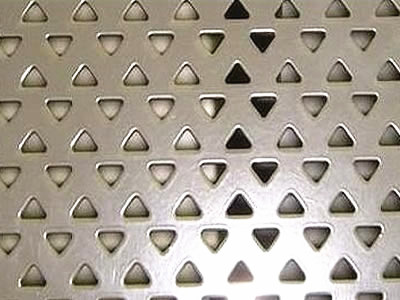

Hot dipped galvanized expanded metal is immersed in liquid zinc up to 500 degrees solution two minutes to make steel mesh attached to the surface of zinc coating thickness of about 10 microns, the surface smooth, shiny, silvery white. Galvanized steel mesh has excellent anti-rust, outdoor use of up to five years without rusting.

Hot dip galvanized steel mesh production process: Finished steel net pickling - washing - plus help bath - drying - rack - cooling - medicated - cleaning - polishing - galvanized completion.

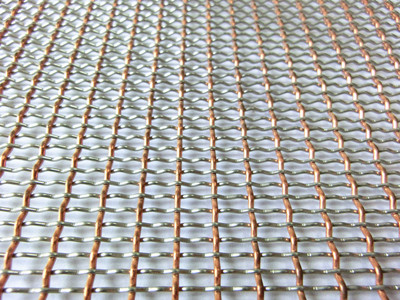

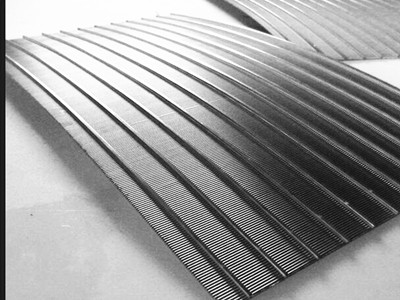

Electric galvanized expanded metal is immersed in the electrolyte by electrolysis half an hour, even in steel mesh surface constitution, fine, contact superior zinc coating thickness of about 2 microns. Galvanized steel net product suitable for indoor, to prevent direct sunlight might rain.

Galvanized steel mesh production process: steel net chemical degreasing → washing → hot water electric hot water to remove oil → washing →→ washing → highly corrosive galvanized iron alloy → washing → washing → light → passivation → washing → monotonous.