Pressure drop and removal efficiency of demister pads

Pressure drop and removal efficiency of demister pads

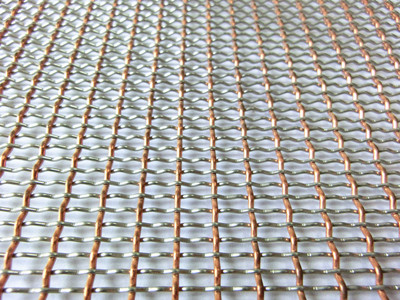

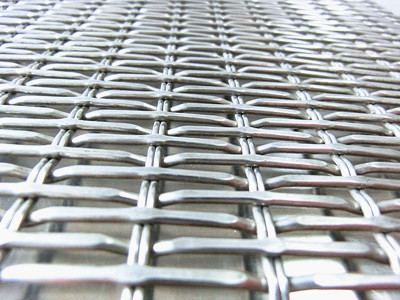

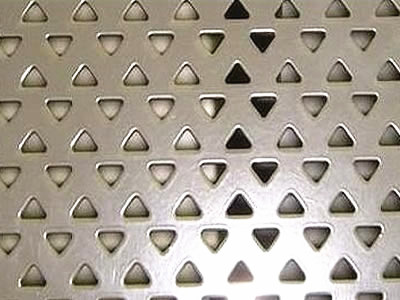

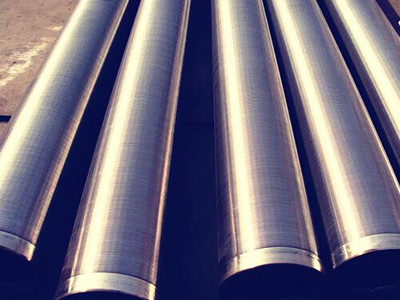

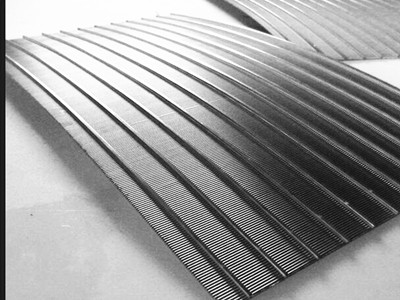

The wet pressure drop was found to increase with increasing the demister specific surface area, packing density, and superficial gas velocity. In contrast, it was found to increase with decreasing the demister void fraction and wire diameter. The pressure drop is correlated empirically as a function of the design parameters.

Generally, The pressure drop through the wire-mesh demister is often small enough to be neglected. For the demister pads can remove droplets down to 5 microns and lower with a free volume of up to

99% and a surface area of up to 1940 m2/m3. Due to high value of free volume the pressure drop across

the demister pad is sufficiently low, negligible for most applications.