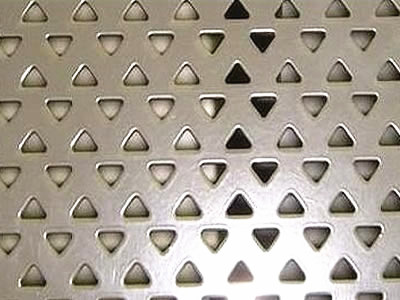

perforated metal mesh production steps

Here are perforated metal mesh production steps:

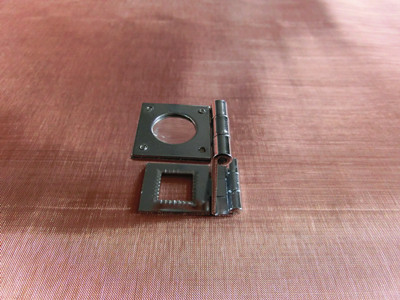

1.Production Model: perforated metal molds results in the quantity of perforated metal design accuracy

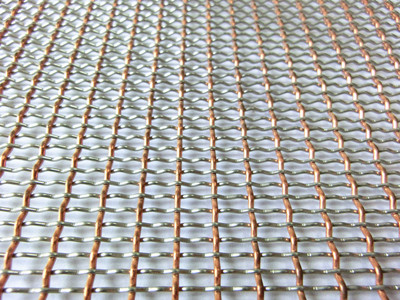

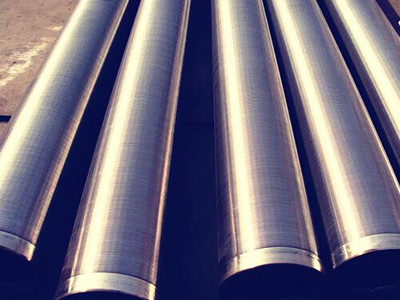

2.With advanced digital control facility, the system can control quality products, output up to 2000 square meters, can be punched in the sheet thickness between 0.1mm-6mm.

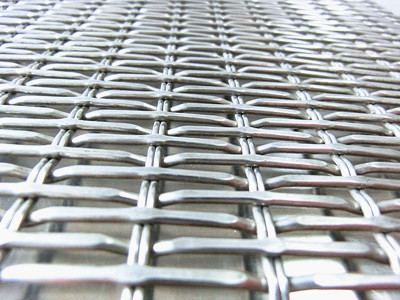

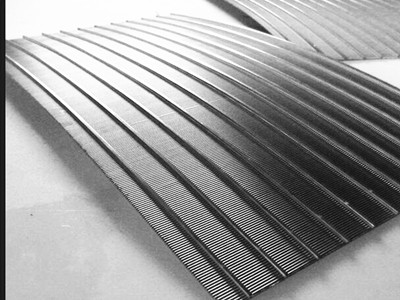

3.Mutilation: cut into the size of your needs from the whole roll material plate.

4.Cutting edge: if the manufacturing process of the board edge over the tolerance range of your requirements, we will help you get rid of your request to get rid of superfluous side.

5.Flattening: we can use a leveler punched through the modification of the punching stainless steel plate to restore its original flat condition. Sheet steel 0.8mm-12mm thickness can be implemented leveling.

6.Cleaning: punching processes require the use of lubricating oils, but we also have a process which can be removed to get rid of the remnants of its appearance, Orifice is clean.

google-site-verification: google66a2e09ce7d6e2d9.html