Manufacturing Considerations

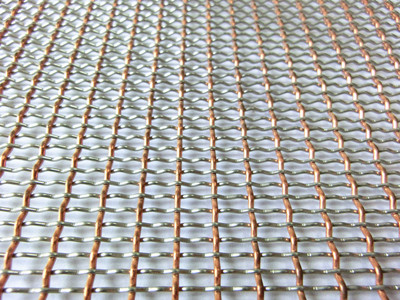

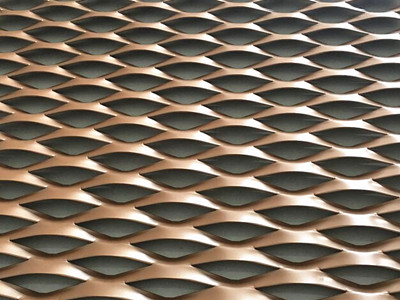

The variables in the expanded product include

Metal type

Metal thickness

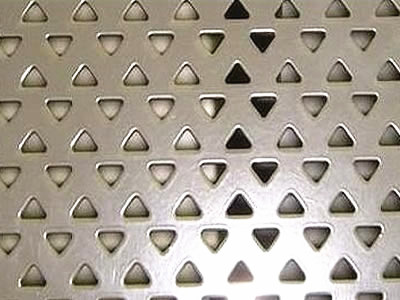

Expanded pattern

Strand width or unit weight

Thickness of expanded product

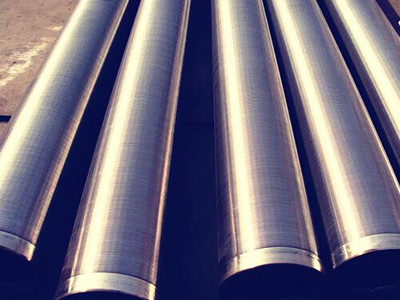

Piece or coil size

The expanding process yields a product whose overall thickness may be 1.5 to 5 times thicker than the base metal.

If the material is flattened, it may be reduced continuously in thickness to 80 percent or less of the original material thickness. Foil material may have the overall thickness increased up to two times the strand width. Strand width can be varied somewhat to change the percentage of open area, thus meeting strength or aesthetic requirements.

Custom manufactured sheet sizes or pieces, or material in coil form, are generally available on special order.

Specific processes used to produce machine Expanded Metal products and additional considerations follow:

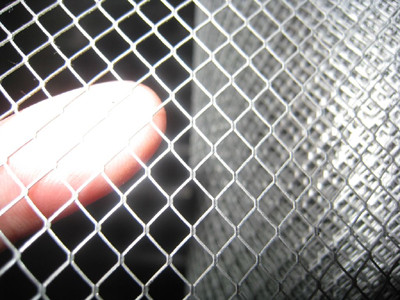

Expanding

An expanding press simultaneously slits and cold forms base material to form a diamond pattern. A sheet of Expanded Metal can be sheared to required size. It can also be manufactured to a specified size in order to eliminate shearing and to reduce waste. A combination of expanding-to-size and shearing can be utilized to attain the final sheet size.

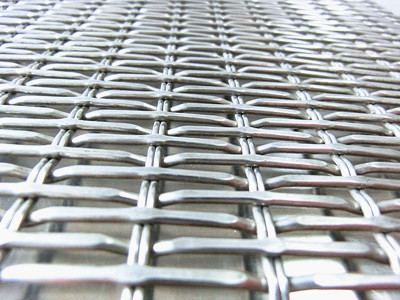

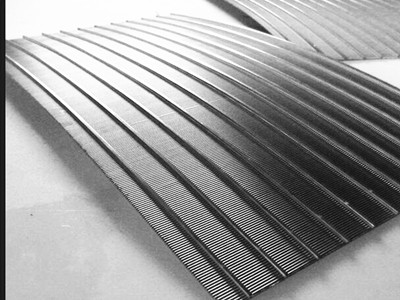

Flattening

The process used to produce flattened Expanded Metal. Most styles and designations may be flattened including some gratings.

Leveling

Expanded Metal is leveled after expansion by either an integral or separate leveling device.

Shearing

Shearing is used to attain a special size and/or tolerance as required. The basic type shearing is random.

In random shearing, the shear line falls at random points on the mesh pattern. Edges are open and diamonds are not matched.