How expanded metal is produced

How expanded metal is produced

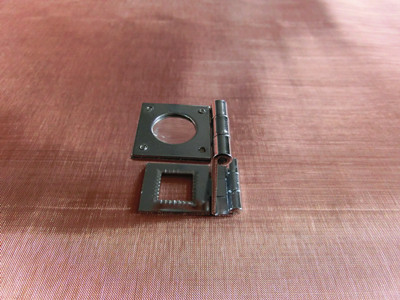

expanded metal processing

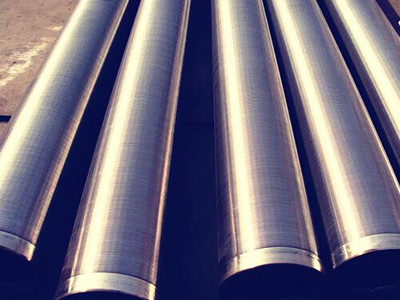

The metal is inserted on rollers or in the form of plates into the rear of the machine.

Each machine is fitted with a special blade which defines the mesh width.

The machines are programmed with the necessary parameters and manually controlled by our qualified employees.

During the elongation process the raw metal sheet is reformed through systematic slitting and predefined stretching. The metal is either formed into rolls or cut to defined sizes.

Advantages of expanded metal

Expanded metal is formed from a single piece of metal. It have the following advantages

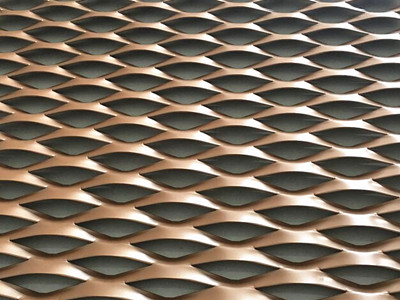

Outstanding corrosion resistance

Our expanded metal is ideal for applications involving industrial acids, for the electroplating of baskets and in seawater for fish cages and lobster pots.When suitably coated, expanded metal mesh, due to the absence of joins and welding seams, offers better performance than woven and welded mesh.

Premium reinforcement properties

Expanded metal works as a barrier for the purposes of security and storage. Our Securilath products impede illegal access through walls and partitions whilst simultaneously strengthening the resilience of the protected area.

Anti-skid surface

The knuckles formed by expanding mesh offer secure grip when deployed for steps, ramps and walkways. We have also developed a range of specific slip-resistant walkway meshes. The purchase obtained through the mesh also enables a multipoint contact with dry racks.

Steps to Cut Expanded Metal

You know, expanded metal is difficult to cut, no matter which shape and form it is. There are some easy ways to cut expanded metal correctly, however, it's also need your patience.

Steps

Measure the expanded metal to mark the area that you want to cut. If possible, it's easiest to cut the metal along the joints where it comes together, but it's not critical.

Clamp the metal ruler to the expanded metal using the clamps, and put it along the measurements you just made. You want this to be exactly along your new mark.

Mark the metal along the ruler using a permanent marker. This is going to be your cut line, so use the tape measure to make sure the measurements are accurate.

Remove the metal ruler and the clamps from the metal. Place the expanded metal onto a raised surface so that your cuts won't go into the concrete or other work surface. Put on the safety glasses and hold the grinder securely and steadily in both hands.

Turn on the grinder and begin to cut the expanded metal. The grinder will throw a lot of sparks, so make sure your eyes are protected. The key is to cut along your marker line while keeping the grinder secure. Each gap in the expanded metal will cause the grinder to move forward, so keep a steady hand as you work down the metal.

Continue to cut until you reach the end of your marks. The metal will separate and the job is complete.

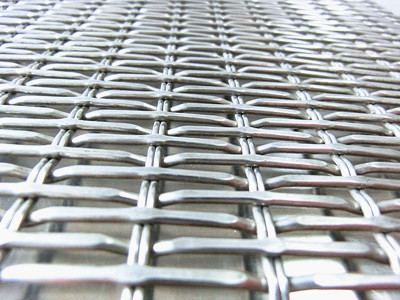

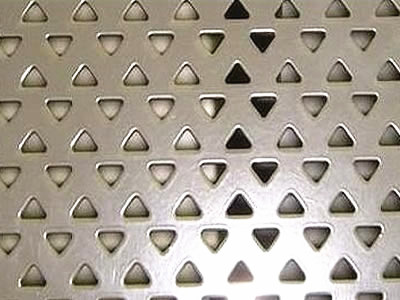

Standard Expanded Metal

Standard Expanded Metal is directly slit and stretched by punching machines without other processing,The strand width and bond come in with an angle with the plate surface. This kind structure increase the strength and hardness of expanded metal,it also brings better anti-slipping and reinforcing performance.

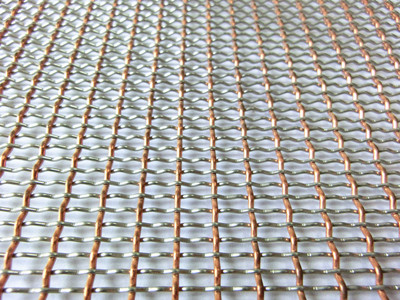

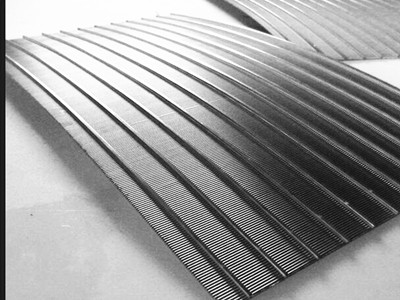

Flattened Expanded Metal

Flattened expanded metal is formed by flattening process based on standard expanded metal. Its strand width and bond are in the same horizontal plane with plate surface. Compared with standard expanded metal,the plate thickness will be thinner and opening will be larger.