Extruder Screen Components

Extruder screens are a key part of any polymer or plastics extrusion process.

There are a few key components to an extruder screen that we want to cover. These components will help you select the best products for your processes.

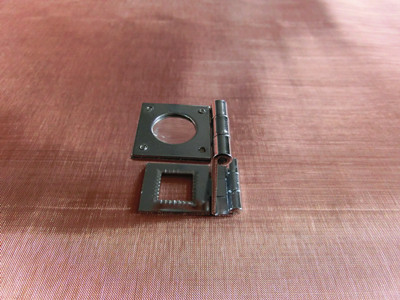

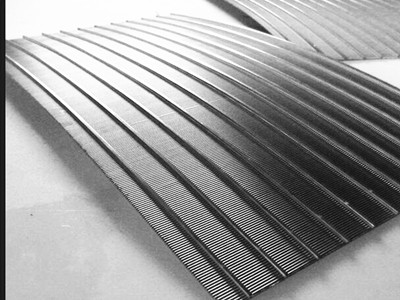

Welding

Your screens need to be welded properly to ensure they don’t bend, stretch or break. This type of effect can alter the opening sizes in your mesh and change your filtration results. This will also result in needing to change your screens more often.

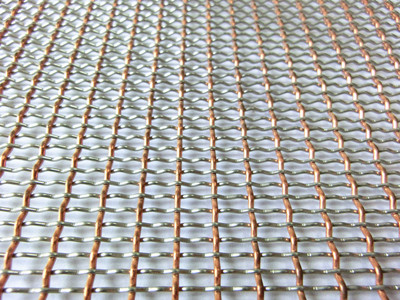

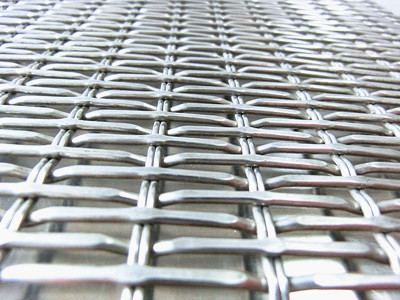

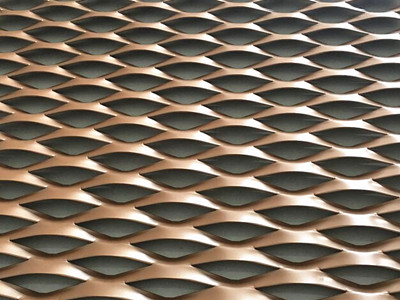

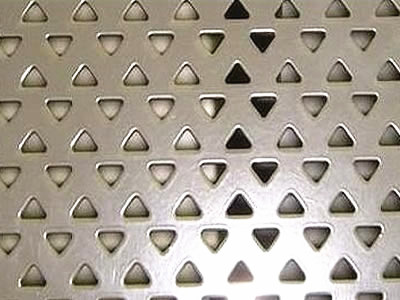

Wire Mesh Screen

The mesh in your screen, whether single-layer or multi-layer, needs to hold up against the material you are filtering. Stainless steel is preferred if the polymer being processed could corrode mild steel, or if the chance for contamination by oxidized steel screen material should be avoided.

Opening size and weave type are also important to the quality of the screen.

Micron ratings/mesh counts vary widely depending on your desired outcome.

Square mesh is most widely used for its flow capability, but filter weaves (Dutch Twill and others) can also be used for finer filtration.

Typical square mesh counts and associated micron ratings will range from 18 mesh (1000 micron) to 500 mesh (25 micron).