Expanded Metal Terminology

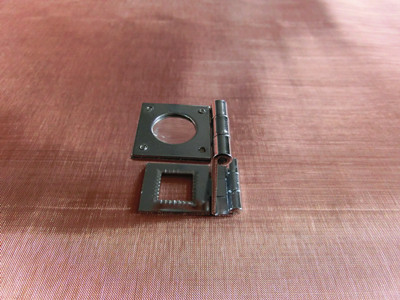

BOND- The point where adjacent strands intersect. The bond is always twice the width of the strand.

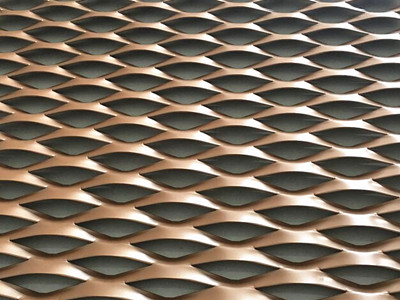

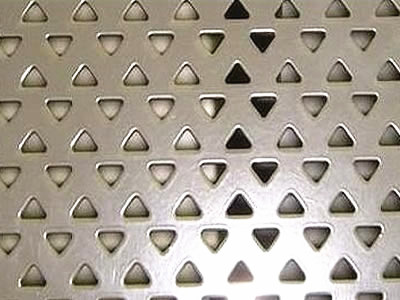

DIAMOND OR OPENING- This is the description of the open area formed by strands and bonds. Normally the open area is diamond shaped.

FORMABILITY- Each piece should be able to withstand a 90 degree bend with a 1/4-inch inside radius in either direction, without fracture.

LEVELING- All expanded metal products except grating are leveled after having been expanded.

LWD OR LWO- Long way of diamond or long way of opening is the dimension measured across the sheet in a direction parallel to the largest dimension of the diamond.

MESH- Description of the expanded metal diamond design.

MESH OPENING SIZE- The area enclosed by bonds and strands.

OUT OF SQUARE- Expanded metal sheets are generally not perfectly square when finished. Sheets must be sheared on all sides for perfect squareness.

OVERALL HEIGHT- This is the finished height of the mesh after expanding or expanding and flattening.

PERCENT OF OPEN AREA- The relation of solid metal to open diamond allowing light, liquids and air to pass.

PITCH- The measurement from a point on one diamond to the same point on an adjacent diamond.

REVERSE DIAMOND- Expanded metal sheets that have their LWD, long way of diamond, coinciding with the short dimension of the sheet; such as with catwalk grating.

STRAND- The single metal strip which forms the border of the diamond, or opening. Strand width is the amount of material advanced for expanding as differentiated from strand thickness which is the thickness of metal from which the expanded metal is produced.

STYLE- Is the name for a specific expanded metal diamond pattern such as 3/4”-#9. When measured this style has no dimension equal to 3/4” and the thickness is not a decimal equivelant to 9-gauge.

SWD OR SWO- Short way of diamond or short way of opening is the dimension measured across the sheet in a direction parallel to the smallest dimension of the diamond.

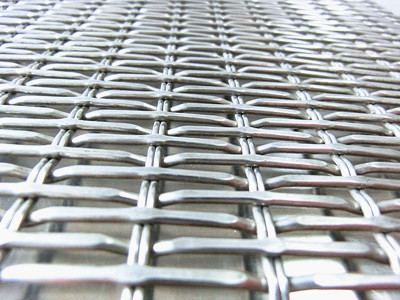

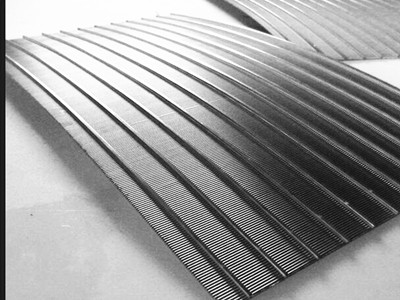

THICKNESS- Begins with the thickness of the base metal. When describing the thickness of expanded metal it should be stated as a decimal not by gauge. Gauge is a marketing term and varies by manufacturer. Flattening expanded metal will further reduce the thickness of the sheet.

EXPANDED METAL GRATING- A heavier load carrying product produced from thicker steel plate. It is typically used for walkways and platforms. Not suitable for vehicular loads.

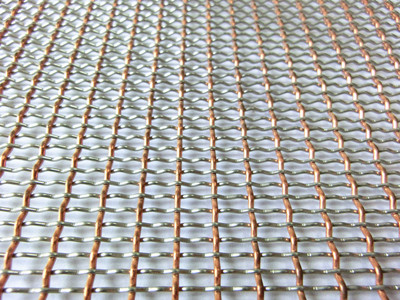

FINISHING- Most commonly carbon steel is hot-dip galvanizing or pre-galvanized. Special finishes such as anodizing, enameling, and plastic coatings can be provided.

REGULAR EXPANDED METAL- Steel is simultaneously slit and stretched into a rigid, non-raveling open mesh panel. It is readily available in carbon steel, aluminum and stainless steel.

FLATTENED EXPANDED METAL- Manufactured by processing regular expanded metal through a rolling mill. This rolling process reduces the thickness and provides a smooth flat sheet.

SHEET SIZE- Expanded metal can be manufactured in many varying sheet sizes. Most common is carbon steel 4’-0” SWD x 8’-0” LWD. Larger sheet sizes can be made up to 7’-0” x 12’-0” on special request and with additional lead time.