Checklist of Perforating Cost Influences

1. Material type

Remember the least expensive material may not be the lowest cost; a higher strength alloy may allow reducing thickness.

2. Material thickness

Thinner materials perforate easier and faster.

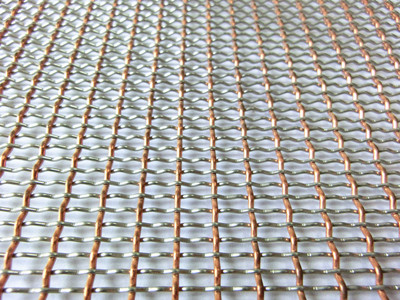

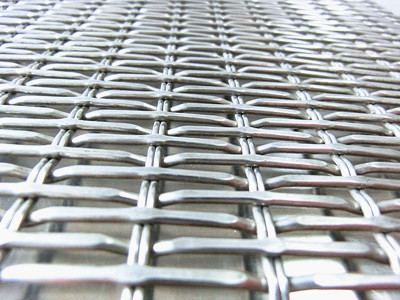

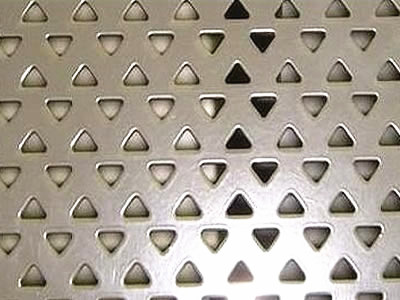

3. Hole shape and pattern

Round holes are the most economical, 60” staggered round hole pattern strongest and most versatile.

4. Hole size

Do not go below 1-to-1 ratio with sheet thickness. Stay at 2-to-1 or larger if possible.

5. Bar size

Do not go thinner than 1 -to-1 ratio with sheet thickness.

6. Center distance

It controls feed rate and thereby the production rate. if possible, choose a pattern with longer

center distance.

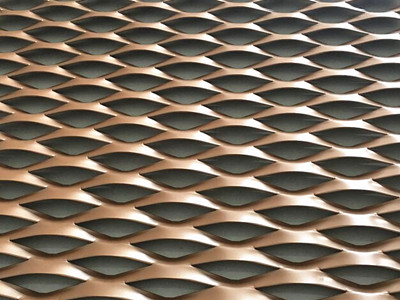

7. Open areas

Extreme open area proportions tend to increase distortion; if possible, stay under 70%.

8. Margins

Keep side margins to a minimum to reduce distortion. Use standard Unfinished End Margins if you can.

9. Blank areas

Consider the die pattern when locating them.

10. Stick to standards

specify standard hole patterns, materials dimensions and tolerances whenever possible.