Battery Metal Mesh

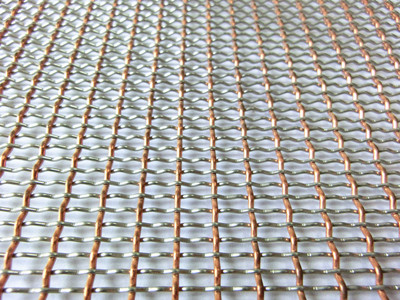

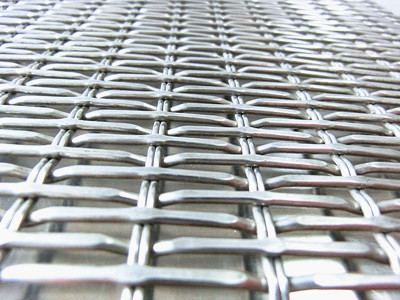

Current collectors of thin film batteries must be flexible, have high surface area, be cost-effective, and allow fluids to flow through them. The expanded metal & perforated metal is generally used as current collectors which usually used as a light frame of the battery and is an important component of the electrode.

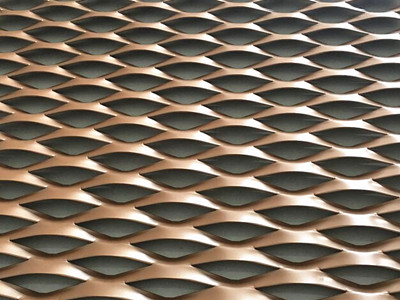

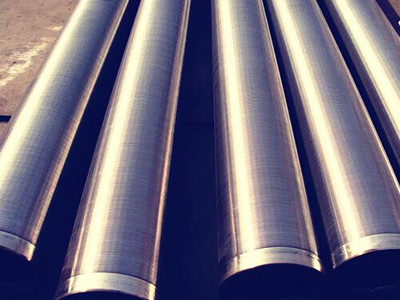

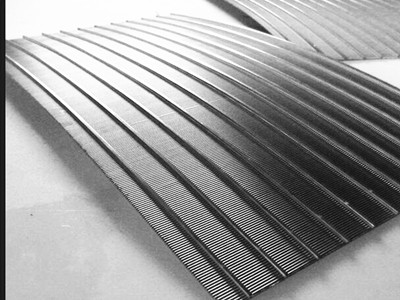

Expanded metal for battery manufacturing

We have redefined how expanded metals can be incorporated into electrolyzers, PEM and other fuel cells. The unique slitting and stretching process yields up to 90% more finish product output than raw material input.

Compared to woven mesh made with thousands of very fine wires, the expanded metal is one body structure which prevents unraveling and fraying.

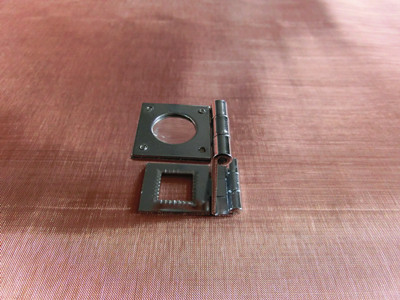

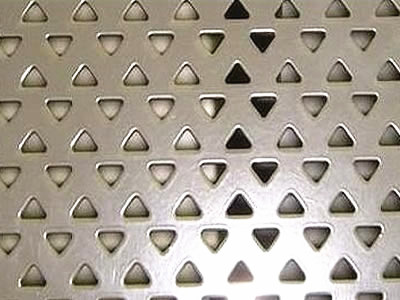

Perforated metal for battery manufacturing

This perforated stainless steel, copper, aluminum, nickel, or other metal foil offers outstanding cost-effectiveness due to the precision tooling and high-speed presses used.

High performance for the cost is achieved by using high-speed press manufacturing.

Foil sheets can be perforated with precise hole patterns (minimum 0.4 mm diameter) and non-perforated areas can be freely specified to create perforated metal foils that are ideal for current collectors used in electrodes for LIC, LIB, EDLC, or other energy storage devices.