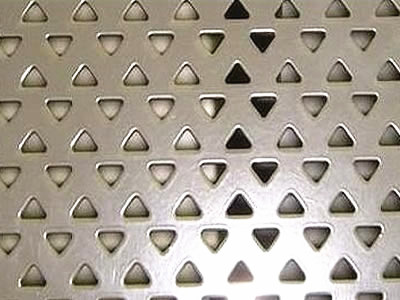

Advantages of stainless steel perforated metal

Advantages of stainless steel perforated metal

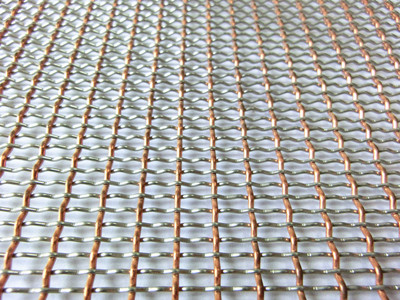

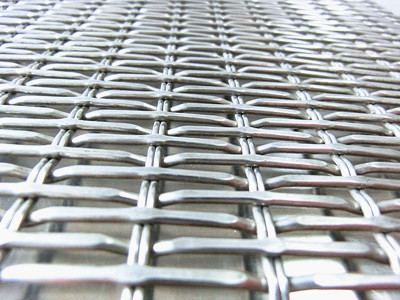

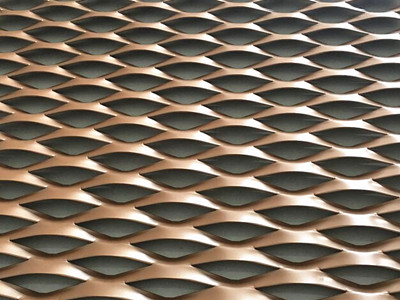

Generally,stainless steel plate material for perforated metal includes 201, 304, 321, 316 and 316L. What exactly difference of these types raw materials?

201 would have been vulgar to say that is all stainless steel iron; 304 stainless steel sheet is the most widely used as raw materials; differences between 316 and 316L stainless steel is the carbon composition, containing varying amounts of nickel. The carbon composition of 316 stainless steel plate is ≤0.08, nickel composition is 10%-14%; carbon composition of 316L stainless steel plate is ≤0.03, nickel composition of 316L is 12%-15%; and the carbon composition of the stainless steel plate 321 is ≤0.08, nickel composition is 9% -13%. 304 material and 316 material are the common stainless steel plate which be used to produce perforated metal.

Using stainless steel plate material,perforated metal can have the following advantages:

1. Corrosion-resistant, non-flammable, non-toxic and tasteless.

2.Good wear resistance and long service life. the wear resistance of stainless steel perforated metal mesh is 3 to 5 times more than normal sieve, at least 5 times more than normal rubber sieve.

3.Low cost in total.While the same standard (area) stainless steel sieve plate punching higher than the average for one-time investment (approximately 2-fold), but for the stainless steel plate service life is 3 to 5 times normal sieve, and fewer in

repair and replacement, so the total cost is not high, the economy is also very cost-effective.

4. Good vibration absorbing performance, high capacity muffler, the noise can be reduced, and allows oscillation sieve material in the process not easily broken.

5. Good moisture resistance. Perforated metal can work under conditions of water as a medium.