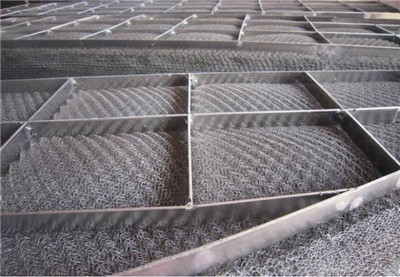

Mesh Demister Pads for Petroleum Refining

Petroleum refining begins with the distillation, or fractionation, of crude oils into separate hydrocarbon groups. The resultant products are directly related to the characteristics of the crude oil being processed. Most of these products of distillation are further converted into more useable products by changing their physical and molecular structures through cracking, reforming and other conversion processes. These products are subsequently subjected to various treatment and separation processes, such as extraction, hydrotreating and sweetening, in order to produce finished products. Whereas the simplest refineries are usually limited to atmospheric and vacuum distillation, integrated refineries incorporate fractionation, conversion, treatment and blending with lubricant, heavy fuels and asphalt manufacturing.

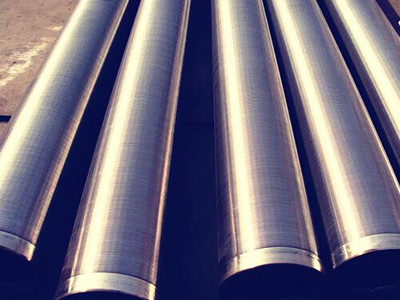

Mist eliminators in fractionators increase throughput capacity and allow deeper cuts for greater yields.

In atmospheric and vacuum pipestills, reduced entrainment from the wash oil zones allows deeper cuts and greater throughput.

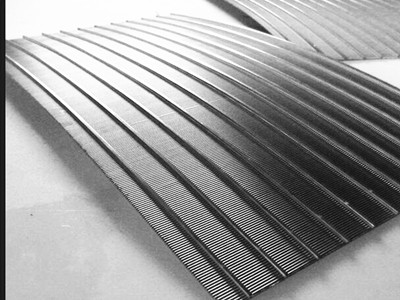

In downstream crackers and reformers, mist eliminators prolong catalyst life by reducing carbon and metals in side draws.

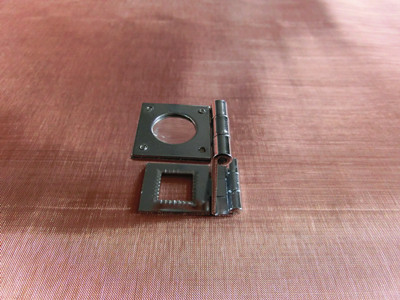

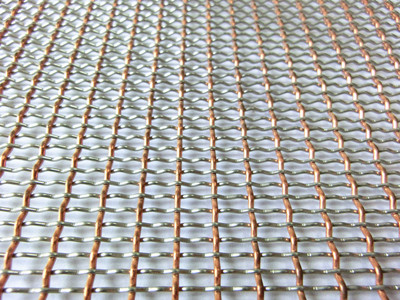

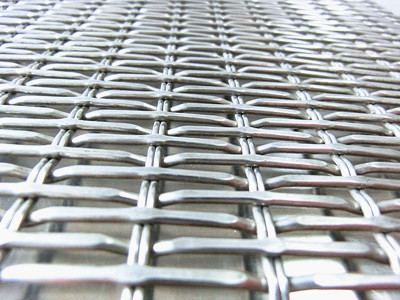

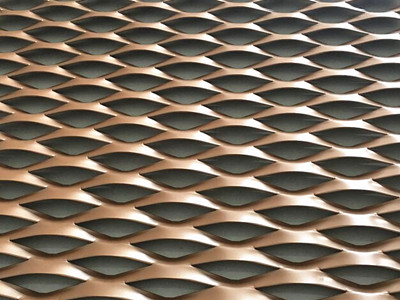

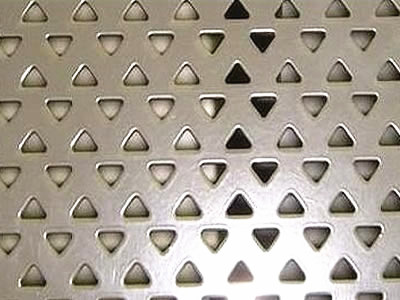

In the above process, Ourun wire mesh can provide the mesh demister pads to meet these requirements.